Understanding Different Types of Temperature Sensors

Understanding Different Types of Temperature Sensors

A temperature sensor is a device that detects and measures temperature through an electrical signal. These sensors are vital in monitoring conditions in homes, industries, and vehicles, providing essential data to maintain temperature control systems.

Temperature sensors operate by detecting changes in temperature and converting this data into an electrical signal. This signal can then be interpreted by a control system to adjust conditions accordingly. In homes, these sensors regulate heating and cooling systems, ensuring comfort and energy efficiency. In vehicles, they monitor engine temperatures to prevent overheating, thus extending the engine’s lifespan. In industrial settings, they ensure processes run smoothly, preventing accidents and ensuring product quality.

The technology used in temperature sensors varies greatly depending on the type and application. Basic sensors, like thermocouples, rely on the Seebeck effect, where a voltage is generated in response to a temperature difference between two dissimilar metals. More advanced sensors, such as infrared models, use thermal radiation to gauge temperature without direct contact. Each type of sensor employs a unique mechanism tailored to specific environments and requirements, showcasing the diversity and adaptability of temperature sensing technologies.

Temperature sensors find applications across a multitude of industries. In the food industry, they ensure that cooking and storage temperatures meet safety standards. In healthcare, they monitor patient body temperatures and help in the sterilization of equipment. The automotive industry utilizes these sensors to optimize engine performance and emissions. Each application demands specific sensor characteristics, demonstrating the importance of selecting the right type of sensor for each unique scenario.

Temperature sensors come in various forms, each designed for specific applications. Here are some of the most common types:

Thermocouples are among the most widely used temperature sensors. They consist of two different metal wires joined at one end, creating a junction where the temperature is measured. The voltage generated by the junction corresponds to the temperature difference between the wires.

Thermocouples are highly versatile and used in numerous industrial settings. They are ideal for measuring high temperatures in gas turbine exhaust systems and industrial furnaces. Their ability to withstand extreme conditions makes them suitable for applications where other sensors might fail. Moreover, their robustness and simplicity make them a favorite for many engineers and technicians.

One of the main advantages of thermocouples is their wide temperature range. They can measure from as low as -200°C to above 2000°C, depending on the type. Their durability under harsh conditions ensures longevity, reducing the need for frequent replacements. Additionally, they are cost-effective, providing reliable temperature measurements without significant financial investment.

Despite their many benefits, thermocouples have some limitations. They tend to be less accurate than other sensor types, particularly at lower temperature ranges. Calibration can also be challenging, as their output voltage is not linear, requiring compensation to achieve accurate readings. Furthermore, thermocouples can be affected by electromagnetic interference, necessitating careful installation and shielding.

RTDs measure temperature by correlating the resistance of the RTD element with temperature. They are made from pure materials, typically platinum, which makes them highly accurate.

RTDs are prevalent in industrial applications where precision is paramount. They are used in chemical processing plants to ensure reactions occur at optimal temperatures. In HVAC systems, RTDs help maintain consistent climate control. Their precision makes them ideal for laboratory experiments where exact temperature measurements are crucial.

The primary advantage of RTDs is their high accuracy and stability over a wide temperature range. They provide consistent and repeatable measurements, essential for quality control processes. Their linearity simplifies the calibration process, allowing for straightforward integration into systems. RTDs are also known for their long-term stability, which is crucial for applications requiring sustained accuracy over time.

While RTDs offer high accuracy, they come with higher initial costs compared to other sensors. They also have a slower response time, which might not be suitable for applications requiring rapid temperature changes. Additionally, RTDs are sensitive to physical shock and vibration, potentially affecting their performance in dynamic environments.

Thermistors are temperature-sensitive resistors with a high level of sensitivity. They are made from ceramic materials and are commonly used in digital temperature sensors.

Thermistors are often used in household appliances like refrigerators and ovens, where they help maintain consistent temperatures. In the automotive industry, they monitor engine coolant and air intake temperatures. Their sensitivity makes them suitable for applications requiring precise temperature control over a narrow range.

Thermistors are highly sensitive, providing accurate readings with small temperature changes. Their small size allows for easy integration into compact devices. They are also cost-effective, offering a budget-friendly solution for temperature sensing. Additionally, their rapid response time is beneficial for applications needing quick temperature monitoring.

Thermistors have a limited temperature range compared to other sensors like thermocouples or RTDs. Their non-linear resistance-temperature relationship can complicate calibration and require complex circuitry for accurate readings. Moreover, they can be more susceptible to environmental factors such as humidity and temperature cycling, potentially affecting their long-term reliability.

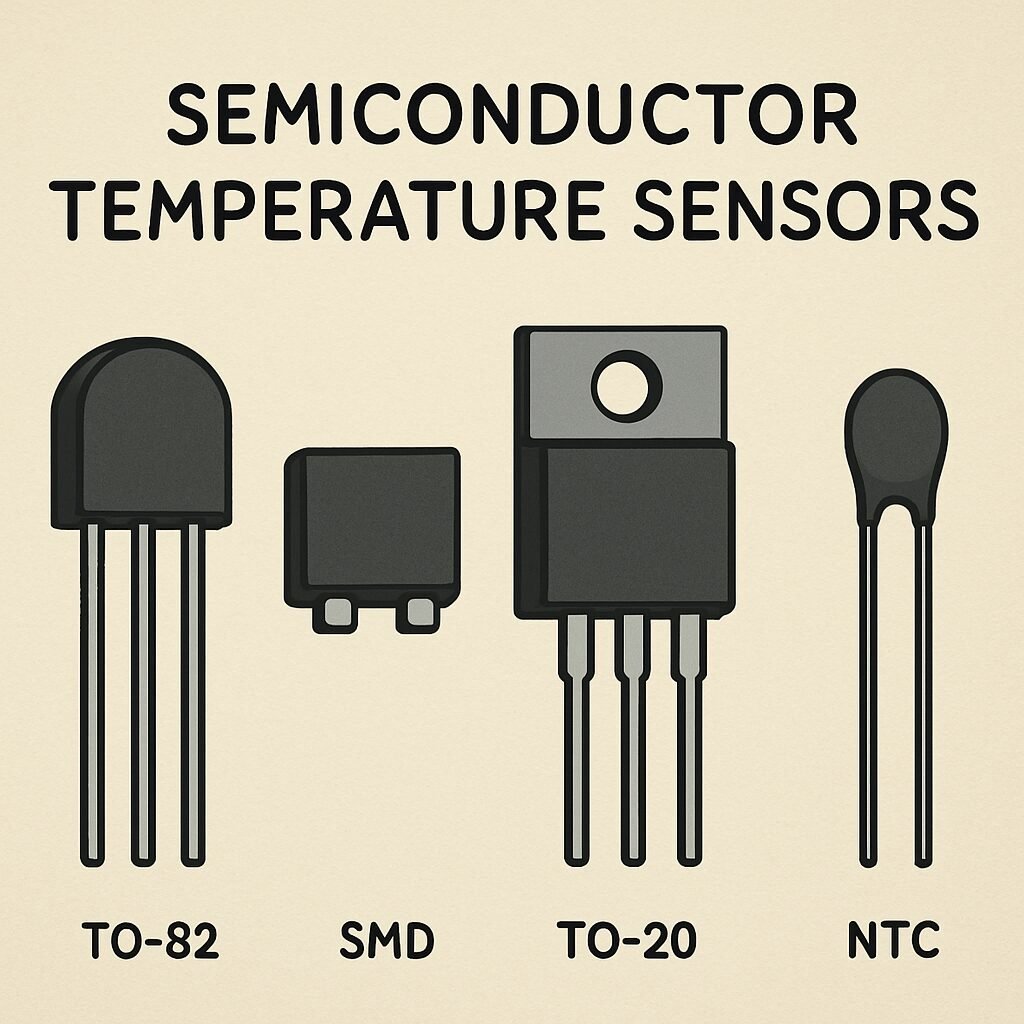

Semiconductor temperature sensors use the properties of semiconductors to measure temperature. They are often used in integrated circuits (ICs).

These sensors are prevalent in consumer electronics, such as smartphones, laptops, and tablets, where compact size and power efficiency are crucial. They are also used in integrated circuits for thermal management of processors. Their versatility extends to automotive applications, where they monitor engine and cabin temperatures.

Semiconductor sensors offer compact size, making them ideal for devices with limited space. Their integration capability with microprocessors and digital systems simplifies design and implementation. They also consume minimal power, making them suitable for battery-operated devices. Furthermore, their digital output eliminates the need for complex analog-to-digital conversion.

One of the main limitations is their restricted temperature range, which is narrower than that of thermocouples or RTDs. They are also sensitive to electrical noise, which can affect accuracy in environments with significant electromagnetic interference. Additionally, their accuracy might not match that of RTDs or thermistors, especially in critical applications requiring precise measurements.

Infrared Sensors

Infrared temperature sensors measure the thermal radiation emitted by an object to determine its temperature. They are non-contact sensors, making them ideal for moving objects or in hazardous environments.

Applications of Infrared Sensors

Infrared sensors are extensively used in medical thermometers for non-contact temperature measurement, reducing the risk of contamination. In industrial settings, they monitor the temperature of moving machinery or conveyor belts. They are also used in HVAC systems to measure surface temperatures of air ducts and walls.

Advantages of Infrared Sensors

The non-contact nature of infrared sensors provides safety and hygiene benefits, especially in medical and food processing applications. They offer a fast response time, essential for dynamic environments where temperatures fluctuate rapidly. Additionally, their ability to measure temperatures from a distance makes them ideal for hazardous or inaccessible areas.

Limitations of Infrared Sensors

Infrared sensors can be affected by environmental factors such as dust, smoke, or moisture, which may interfere with the accuracy of readings. Their performance can also vary depending on the emissivity of the target surface, requiring calibration for different materials. Furthermore, they tend to be more expensive than contact sensors, which can be a consideration for budget-conscious projects.

Digital Temperature Sensors

Digital temperature sensors, such as the DS18B20, provide temperature readings in digital format. They are easy to interface with microcontrollers and are commonly used in DIY projects and Arduino applications.

Applications of Digital Temperature Sensors

Digital sensors are widely used in home automation systems, providing precise temperature data for smart thermostats. They are also employed in server room monitoring, where maintaining optimal temperatures is critical to prevent equipment failure. DIY enthusiasts often use them in projects involving microcontrollers like Arduino or Raspberry Pi.

Advantages of Digital Temperature Sensors

The digital output of these sensors simplifies interfacing with digital systems, reducing the need for additional circuitry. They offer high precision, making them suitable for applications where accuracy is crucial. Their compact design allows for easy installation in space-constrained environments. Additionally, they often support communication protocols like I2C or SPI, enhancing compatibility with various devices.

Limitations of Digital Temperature Sensors

While digital sensors offer many benefits, they may have limitations in terms of temperature range and environmental robustness. Their reliance on digital communication can introduce latency, affecting response times in fast-changing environments. Additionally, their accuracy may degrade over time if not properly calibrated or maintained.

Temperature Probes

Temperature probes are contact temperature sensors that can detect temperature changes in fluids, solids, or gases. They come in various forms, including immersion probes and surface probes.

Applications of Temperature Probes

Temperature probes are essential in laboratory settings for precise temperature measurements of solutions or reactions. In the food industry, they monitor cooking temperatures to ensure food safety standards. In automotive applications, they measure oil or coolant temperatures to optimize engine performance. Newest in the store

Advantages of Temperature Probes

Temperature probes offer versatility, with designs suitable for various media and environments. They provide accurate and reliable readings, essential for quality control and process optimization. Their straightforward design makes them easy to use and integrate into existing systems. Additionally, they are available in different materials and sizes, catering to specific application needs.

Limitations of Temperature Probes

The main limitation of temperature probes is their need for direct contact with the measured medium, which can affect their longevity in corrosive or abrasive environments. They may also have slower response times compared to non-contact sensors, limiting their use in fast-changing temperature conditions. Furthermore, their installation might require specific fittings or equipment, increasing setup complexity.

Specialized Temperature Sensors

Certain applications require specialized temperature sensors to meet specific needs.

Low Temperature Sensors

Low temperature sensors are designed for applications requiring precise temperature measurement at sub-zero temperatures.

Applications of Low Temperature Sensors

These sensors are vital in cryogenic applications, such as liquefied gas storage and superconductor research. In refrigeration systems, they ensure temperatures remain within safe limits to prevent spoilage. They are also used in aerospace applications, monitoring temperatures in extreme environments encountered at high altitudes.

Advantages of Low Temperature Sensors

Low temperature sensors provide high precision and reliability, critical for processes that require exact temperature control. They are designed to operate effectively at extremely low temperatures, ensuring consistent performance. Their robust construction allows them to withstand the stresses associated with cryogenic conditions.

Limitations of Low Temperature Sensors

One limitation is their specialized design, which can make them more expensive than standard temperature sensors. They may also have limited availability, requiring sourcing from specialized manufacturers. Additionally, their performance can be influenced by factors like thermal expansion or contraction, necessitating careful calibration and maintenance.

Industrial Temperature Sensors

Industrial temperature sensors are robust and built to withstand harsh conditions typically found in industrial environments.

Applications of Industrial Temperature Sensors

These sensors are used in chemical processing plants to ensure safe and efficient reactions. In power plants, they monitor boiler and turbine temperatures to optimize energy production. They are also employed in the manufacturing sector, where they ensure equipment operates within safe temperature ranges.

Advantages of Industrial Temperature Sensors

Industrial sensors are designed for durability, with materials that resist corrosion, vibration, and high temperatures. They offer a wide temperature range, accommodating various industrial processes. Their reliability reduces downtime, enhancing overall productivity. Additionally, their robust design ensures longevity, minimizing the need for frequent replacements.

Limitations of Industrial Temperature Sensors

While industrial sensors are robust, their complexity can increase installation and maintenance costs. Their design might be over-specified for less demanding applications, leading to unnecessary expense. Additionally, their size and weight can be a consideration in space-constrained environments.

Wireless Temperature Sensors

Wireless temperature sensors offer the advantage of remote monitoring and data collection without the need for extensive wiring.

Applications of Wireless Temperature Sensors

These sensors are ideal for building automation systems, providing real-time temperature data for efficient climate control. In environmental monitoring, they track temperature changes in remote or difficult-to-access locations. They are also used in logistics, monitoring the temperature of perishable goods during transport.

Advantages of Wireless Temperature Sensors

Wireless sensors offer flexible installation, as they can be placed without the constraints of wiring. They provide real-time data access, enabling prompt response to temperature changes. Their remote monitoring capability enhances convenience and efficiency, particularly in large or complex installations.

Limitations of Wireless Temperature Sensors

One limitation is their reliance on wireless networks, which can be affected by interference or connectivity issues. Their battery life can also be a concern, requiring regular maintenance or replacement. Additionally, their initial setup may involve higher costs compared to wired sensors.

How Many Coolant Temperature Sensors Are in a Car?

Automobiles typically use multiple coolant temperature sensors to monitor engine temperature and ensure optimal performance. These sensors help manage engine efficiency, reduce emissions, and prevent overheating.

Role in Engine Management

Coolant temperature sensors play a critical role in engine management systems. They provide data to the engine control unit (ECU), which adjusts fuel injection and ignition timing for optimal performance. Accurate temperature readings ensure the engine operates efficiently, reducing fuel consumption and emissions. By preventing overheating, these sensors also protect the engine from damage and extend its lifespan.

Applications in HVAC Systems

HVAC systems rely on temperature sensors to maintain comfortable indoor temperatures and optimize energy usage.

Room Temperature Sensors

Room temperature sensors measure ambient temperature, providing data to adjust heating and cooling systems. They ensure consistent comfort levels while minimizing energy consumption. In smart homes, these sensors integrate with automation systems to optimize climate control based on occupancy and preferences.

Outdoor Temperature Sensors

Outdoor temperature sensors provide data on external conditions, allowing HVAC systems to adjust indoor climate accordingly. By anticipating weather changes, these sensors help maintain stable indoor environments. They also contribute to energy savings by optimizing heating and cooling operations based on real-time outdoor temperatures.

Duct Temperature Sensors

Duct temperature sensors monitor air temperature within HVAC ducts, ensuring systems operate efficiently. They detect temperature fluctuations, prompting adjustments to maintain consistent airflow. These sensors are crucial for preventing energy waste and ensuring effective heating and cooling distribution throughout a building.

Selecting the Right Temperature Sensor

Choosing the right temperature sensor depends on several factors:

Measurement Range

Ensure the sensor can accurately measure the required temperature range. Consider both the minimum and maximum temperatures your application will encounter. A sensor with an inadequate range might provide inaccurate readings, affecting system performance. It’s important to match the sensor’s range with the specific environmental conditions it will face.

Environment

Consider environmental conditions such as humidity, pressure, and exposure to chemicals. Harsh environments may require sensors with protective coatings or housings. In corrosive settings, materials like stainless steel or Teflon might be necessary to ensure durability. Understanding the environmental factors will help in selecting a sensor that maintains accuracy and reliability over time.

Response Time

Determine how quickly the sensor needs to respond to temperature changes. Fast response times are crucial for dynamic environments where temperatures fluctuate rapidly. In contrast, slower response times might suffice for applications with gradual temperature changes. Evaluating the response time requirements will ensure the sensor aligns with the application’s needs.

Accuracy

Decide on the level of precision required for the application. High-precision sensors are essential for applications with strict temperature tolerances. However, they may come at a higher cost. Balancing accuracy with budget constraints is key to selecting a sensor that meets performance expectations without overspending.

Cost

Consider the budget and find a sensor that offers the best value for money. Evaluate the total cost of ownership, including installation, maintenance, and potential replacements. It’s important to weigh the initial investment against long-term benefits, ensuring the chosen sensor delivers the desired performance and reliability.

Conclusion

Temperature sensors are integral to many systems, providing critical data for temperature monitoring and control. By understanding the different types of temperature sensors and their applications, you can make informed decisions to select the best sensor for your specific needs. Whether it’s for industrial use, automotive applications, or home automation, the right temperature sensor will enhance performance, safety, and efficiency.

Temperature sensors not only ensure optimal operation but also contribute to the sustainability of systems by enhancing energy efficiency. As technology advances, the development of more sophisticated sensors will continue to drive innovation across various industries, highlighting the importance of staying informed about the latest advancements. Selecting the right sensor requires careful consideration of application requirements, environmental conditions, and budget constraints, ensuring systems operate reliably and efficiently.